Mechanical Engineering (ME)

Mechanical Engineering (ME) is the discipline that applies Engineering Physics and Materials Science principles to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest engineering disciplines. It also interfaces with Electrical and Electronic Devices to enhance performance and efficiency in Design and Manufacturing through Automation and Robotics. Nowadays, Mechanical Engineering programme play a crucial role in operating machinery with minimal manpower, delivering highly profitable and reliable products that satisfy customer demands.

Now, in undergraduate (UG) has an intake of 60 students. Additionally, the department introduced a postgraduate (PG) program in Production Engineering & Engineering Design (PE & ED) with an intake of 24 students.

The department has obtained permanent affiliation with JNTUA for all its UG and PG programs. The department has developed its Vision, Mission, Program Outcomes (POs), Program Specific Outcomes (PSOs), and Program Educational Objectives (PEOs) and also mapped them. Course Outcomes (COs) for all the courses are enlisted and CO attainment metrics are also available. The teaching-learning system unites various Outcome Based Education (OBE) methods and strategies like organizing Quality Control (QC) activities.

Furthermore, the department has a ‘Student Club Association’ through which students are allowed to enrich their technical knowledge by attending / participating in National-Level Workshops, Seminars, and Working Models Exhibitions.

Vision

To achieve Excellence in the field of Mechanical Engineering with Professional Competency.

Mission

- Strict adherence to the curriculum requirements for the overall development of learners.

- Improve the facilities to meet the mechanical engineering programme needs.

- Best utilize Industry Institute linkages to acquire professional competency.

- Encourage Innovative Research to address new challenges and improve social requirements.

Programme Educational Objectives

| PEO No. | Programme Educational Objectives |

|---|---|

| PEO1 | Develop problem solving approach using analytical abilities, effective communication skills and teamwork |

| PEO2 | Equip students with modern tools, technology and advanced software’s to become a life-long learner for professional growth. |

| PEO3 | The Graduate becomes lifelong learner for professional development |

Programme Specific Outcomes

The Programme Specific Outcomes (PSOs) of UG in Mechanical Engineering (ME):

| PSO | Programme Specific Outcome |

|---|---|

| PSO1 | Design and Development: Analyze the various concepts of design, production, and thermal fluid sciences to solve engineering difficulties by utilizing advanced technology. |

| PSO2 | Apply novel tools (software packages and machinery) to improve the functionality of components in the realm of engineering practice. |

Programme Outcomes

The department of ME has developed and adopted Programme Outcomes (POs) for guiding UG programme. POs describe that, what students are expected to know or be able to do by the time of graduation from the programme.The Programme Outcomes of UG in Mechanical Engineering (ME):

| PO | Programme Outcome |

|---|---|

| PO1 | Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems. |

| PO2 | Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences. |

| PO3 | Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations. |

| PO4 | Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions. |

| PO5 | Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations. |

| PO6 | The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice. |

| PO7 | Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development. |

| PO8 | Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice. |

| PO9 | Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings. |

| PO10 | Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions. |

| PO11 | Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments. |

| PO12 | Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change. |

COs

Dr. B Sudheer Reddy is an Associate Professor and Head of the Department of Mechanical Engineering. He received his Bachelor of Technology (B.Tech) and Master of Technology (M.Tech) degrees in Mechanical Engineering from JNTU-A, Ananthapur, A.P. He obtained his Doctoral Degree (Ph.D.) from Vellore Institute of Technology (VIT), Vellore, in the year 2022. He has about 7 years of teaching and research experience. His current research focuses on Surface Engineering, Tribology, Manufacturing, and Optimization through Machine Learning techniques.

Dr. Reddy has published a total of Sixteen (16) articles, including Six (6) research articles in peer-reviewed journals (Scopus Indexed Journal and Thomson Reuter Journals), five (5) international publications, four (4) book chapters in reputed publications, one (1) conference proceedings and a few more (five (5)) research articles are under review in peer-reviewed journals. He also claimed a design patent on “wrist band for school children security” – Indian Patent Application No. 375562-001. Dr. B Sudheer Reddy is an active member of professional bodies like Tribology Society of India (TSI), Institute for Educational Research and Publication (IFERP), International Society for Research and Development (ISRD), and International Association of Engineers (IAENG). He has been a member of various Technical and Non-technical committees in the AITS, Tirupati. He is a Ratified faculty member under JNTUA, Ananthapuramu-515002.

FACULTY MEMBERS IN THE ACADEMIC YEAR 2024-25

| S.No. | Name | Qulaification | Designation | Date of Joining | Nature of Association (Regular/Contractual) |

| 1 | Dr. C Nadhamuni Reddy | Ph.D | Principal & Professor | 03.08.2015 | Regular |

| 2 | Dr. J Venumurali | Ph.D | Professor | 10.11.2021 | Regular |

| 3 | Dr. PC Elumalai | Ph.D | Associate Professor | 16.05.2022 | Regular |

| 4 | Dr. M Chaitanya Reddy | Ph.D | Associate Professor | 24.11.2021 | Regular |

| 5 | Dr. B. Sudheer Reddy | Ph.D | Associate Professor | 21.09.2022 | Regular |

| 6 | Dr.K Kumar | Ph.D | Associate Professor | 08.08.2011 | Regular |

| 7 | Dr. M Maruthi rao | Ph.D | Professor | 14.06.2023 | Regular |

| 8 | M Balaji | M.Tech(Ph.D) | Assistant Professor | 30.07.2014 | Regular |

| 9 | P C Prakash | M.Tech | Assistant Professor | 17.12.2015 | Regular |

| 10 | S Siva Shankar | M.Tech(Ph.D) | Assistant Professor | 03.10.2017 | Regular |

| 11 | K Rajasekhar | M.Tech | Assistant Professor | 01.08.2018 | Regular |

| 12 | k Vinay Kumar | M.Tech | Assistant Professor | 11.02.2022 | Regular |

| 13 | S Praveena | M.Tech | Assistant Professor | 15.06.2015 | Regular |

| 14 | K Gowthami | M.Tech | Assistant Professor | 01.08.2019 | Regular |

| 15 | S Lakshmi | M.Tech | Assistant Professor | 08.01.2021 | Regular |

| 16 | N V Puneeth Kumar | M.Tech | Assistant Professor | 07.06.2017 | Regular |

| 17 | Sali Nishanthi | M.Tech | Assistant Professor | 05.08.2015 | Regular |

| 18 | T Anji babu | M.Tech | Assistant Professor | 20.10.2020 | Regular |

| 19 | V Chengal Reddy | M.Tech(Ph.D) | Assistant Professor | 29.08.2022 | Regular |

| 20 | T Nishkala | M.Tech | Assistant Professor | 29.08.2022 | Regular |

| 21 | P Indraprasta | M.Tech | Assistant Professor | 29.06.2019 | Regular |

| 22 | V Lokesh | M.Tech | Assistant Professor | 17.07.2023 | Regular |

| 23 | A Rohansatya Sai | M.Tech | Assistant Professor | 17.07.2023 | Regular |

| 24 | S Raviteja | M.Tech | Assistant Professor | 29.07.2024 | Regular |

| 25 | G Nitheesh Kumar | M.Tech | Assistant Professor | 01.08.2024 | Regular |

| 26 | Dudekula Dastagiri | M.Tech | Assistant Professor | 25.07.2024 | Regular |

FACULTY MEMBERS IN ACADEMIC YEAR 2023-24

| S. No. | Name | Qualification | Designation | Gender | Aadhar No | PAN No. | Area of Specialization | Date of Joining | Date on which Designated as Professor/ Associate Professor |

Currently Associated (Y/N) |

Ratified (Yes/No) | Date of Leaving (In case Currently Associated is “No”) |

| 1 | Dr. C Nadhamuni Reddy | Ph.D | Principal & Professor | Male | 414306713004 | ABAPC 5515H | Industrial Engineering | 03.08.2015 | 03.08.2015 | Yes | Yes | |

| 2 | Dr. J Venumurali | Ph.D | Professor | Male | 819973470593 | APSPJ6485P | Manufacturing | 10.11.2021 | 10.11.2021 | Yes | Yes | |

| 3 | Dr. PC Elumalai | Ph.D | Associate Professor | Male | 374595024048 | AWJPP8360M | Manufacturing | 16.05.2022 | 16.05.2022 | Yes | Yes | |

| 4 | Dr. M Chaitanya Reddy | Ph.D | Associate Professor | Male | 966941696517 | AJCPC4257C | Manufacturing | 24.11.2021 | 24.11.2021 | Yes | Yes | |

| 5 | Dr. B. Sudheer Reddy | Ph.D | Associate Professor | Male | 251689301009 | BTPPB0222G | Advanced Manufacturing Systems | 21.09.2022 | 21.09.2022 | Yes | Yes | |

| 6 | Dr.K Kumar | Ph.D | Associate Professor | Male | 308790114558 | BHYPK5057K | Nano Science | 08.08.2011 | 08.08.2011 | Yes | Yes | |

| 7 | Dr. M Maruthi rao | Ph.D | Professor | Male | 501751387322 | AQTPM2777M | Heat power, R&AC | 14.06.2023 | 14.06.2023 | Yes | Yes | |

| 8 | M Balaji | M.Tech(Ph.D) | Assistant Professor | Male | 754778934056 | CEEPM1233F | Advanced IC Engines | 30.07.2014 | Yes | Yes | ||

| 9 | P C Prakash | M.Tech | Assistant Professor | Male | 711696954973 | BPAPP2018B | PEED | 17.12.2015 | Yes | Yes | ||

| 10 | S Siva Shankar | M.Tech(Ph.D) | Assistant Professor | Male | 541791092137 | HLZPS2815G | CADCAM | 03.10.2017 | Yes | Yes | ||

| 11 | K Rajasekhar | M.Tech | Assistant Professor | Male | 934875350077 | DWZPK0016G | CADCAM | 01.08.2018 | Yes | Yes | ||

| 12 | C.JAY SHYAM | M.Tech | Assistant Professor | Male | 495106697257 | AVXPC9841M | PEED | 08.07.2019 | Yes | No | 30.04.2024 | |

| 13 | k Vinay Kumar | M.Tech | Assistant Professor | Male | 581158859150 | ANIPV7124R | CADCAM | 11.02.2022 | Yes | Yes | ||

| 14 | S Praveena | M.Tech | Assistant Professor | Female | 799878705432 | CWCPS4206C | CADCAM | 15.06.2015 | Yes | Yes | ||

| 15 | K Gowthami | M.Tech | Assistant Professor | Female | 83066693536 | BZJPK4632F | Machine Design | 01.08.2019 | Yes | No | ||

| 16 | S Lakshmi | M.Tech | Assistant Professor | Female | 902690606827 | BCJPA6063R | CADCAM | 08.01.2021 | Yes | Yes | ||

| 17 | M Sruthi | M.Tech | Assistant Professor | Female | 548023539960 | CTCPM0520L | Advanced Manufacturing Systems | 01.11.2021 | Yes | Yes | 30.04.2024 | |

| 18 | N V Puneeth Kumar | M.Tech | Assistant Professor | Male | 880261849891 | ARYPN1891P | Mechatronics | 07.06.2017 | Yes | Yes | ||

| 19 | Sali Nishanthi | M.Tech | Assistant Professor | Female | 696933111724 | EQIPS3233R | CADCAM | 05.08.2018 | Yes | Yes | ||

| 20 | T Anji babu | M.Tech | Assistant Professor | Male | 235668227072 | AZFPT8655E | CADCAM | 20.10.2020 | Yes | No | ||

| 21 | V Chengal Reddy | M.Tech(Ph.D) | Assistant Professor | Male | 4238 5256 1791 | ANMPV5879K | Machine Design | 29.08.2022 | Yes | Yes | ||

| 22 | T Nishkala | M.Tech | Assistant Professor | Female | 735663334066 | AODPN4298L | CADCAM | 29.08.2022 | Yes | Yes | ||

| 23 | P Indraprasta | M.Tech | Assistant Professor | Female | 536161895093 | CBSPP5125Q | R&AC | 29.06.2019 | Yes | No | ||

| 24 | V Lokesh | M.Tech | Assistant Professor | Male | 405143819580 | AEWPL8571P | CADCAM | 17.07.2023 | Yes | No | ||

| 25 | A Rohansatya Sai | M.Tech | Assistant Professor | Male | 673528465700 | BROPA8297D | Advanced Manufacturing systems | 17.07.2023 | Yes | No | ||

| 26 | S B V J Chandbadshah | M.Tech(Ph.D) | Assistant Professor | Male | 403108474472 | BUNPB8730L | Mechatronics | 20.07.2015 | No | Yes | 31.07.2023 | |

| 27 | T Niranjanbabu | M.Tech | Assistant Professor | Male | 522021077699 | AKDPT7582M | INDUSTRIAL ENGINEERING | 11.03.2017 | No | No | 31.07.2023 |

FACULTY MEMBERS IN ACADEMIC YEAR 2022-23

| S. No. | Name | Qualification | Designation | Gender | Aadhar No | PAN No. | Area of Specialization | Date of Joining | Date on which Designated as Professor/ Associate Professor |

Currently Associated (Y/N) |

Ratified (Yes/No) | Date of Leaving (In case Currently Associated is “No”) |

| 1 | Dr. C Nadhamuni Reddy | Ph.D | Principal & Professor | Male | 414306713004 | ABAPC 5515H | Industrial Engineering | 03.08.2015 | 03.08.2015 | yes | Yes | |

| 2 | Dr. J Venumurali | Ph.D | Professor | Male | 819973470593 | APSPJ6485P | Manufacturing | 10.11.2021 | 10.11.2021 | yes | Yes | |

| 3 | Dr. PC Elumalai | Ph.D | Associate Professor | Male | 374595024048 | AWJPP8360M | Manufacturing | 16.05.2022 | 16.05.2022 | yes | Yes | |

| 4 | Dr. M Chaitanya Reddy | Ph.D | Associate Professor | Male | 966941696517 | AJCPC4257C | Manufacturing | 24.11.2021 | 24.11.2021 | yes | Yes | |

| 5 | Dr. B. Sudheer Reddy | Ph.D | Associate Professor | Male | 251689301009 | BTPPB0222G | Advanced Manufacturing Systems | 21.09.2022 | 21.09.2022 | yes | Yes | |

| 6 | Dr.K Kumar | Ph.D | Associate Professor | Male | 308790114558 | BHYPK5057K | Nano Science | 08.08.2011 | 08.08.2011 | yes | Yes | |

| 7 | Dr. M Maruthi rao | Ph.D | Professor | Male | 501751387322 | AQTPM2777M | Heat power, R&AC | 14.06.2023 | 14.06.2023 | yes | Yes | |

| 8 | M Balaji | M.Tech(Ph.D) | Assistant Professor | Male | 754778934056 | CEEPM1233F | Advanced IC Engines | 30.07.2014 | yes | Yes | ||

| 9 | P C Prakash | M.Tech | Assistant Professor | Male | 711696954973 | BPAPP2018B | PEED | 17.12.2015 | yes | Yes | ||

| 10 | C.JAY SHYAM | M.Tech | Assistant Professor | Male | 495106697257 | AVXPC9841M | PEED | 08.07.2019 | yes | No | ||

| 11 | S Siva Shankar | M.Tech(Ph.D) | Assistant Professor | Male | 541791092137 | HLZPS2815G | CADCAM | 03.10.2017 | yes | Yes | ||

| 12 | K Rajasekhar | M.Tech | Assistant Professor | Male | 934875350077 | DWZPK0016G | CADCAM | 01.08.2018 | yes | Yes | ||

| 13 | k Vinay Kumar | M.Tech | Assistant Professor | Male | 581158859150 | ANIPV7124R | CADCAM | 11.02.2022 | yes | Yes | ||

| 14 | M Sruthi | M.Tech | Assistant Professor | Female | 548023539960 | CTCPM0520L | Advanced Manufacturing Systems | 01.11.2021 | yes | Yes | ||

| 15 | S Praveena | M.Tech | Assistant Professor | Female | 799878705432 | CWCPS4206C | CADCAM | 15.06.2015 | yes | Yes | ||

| 16 | K Gowthami | M.Tech | Assistant Professor | Female | 83066693536 | BZJPK4632F | Machine Design | 01.08.2019 | yes | Yes | ||

| 17 | S Lakshmi | M.Tech | Assistant Professor | Female | 902690606827 | BCJPA6063R | CADCAM | 08.01.2021 | yes | Yes | ||

| 18 | N V Puneeth Kumar | M.Tech | Assistant Professor | Male | 880261849891 | ARYPN1891P | Mechatronics | 07.06.2017 | yes | Yes | ||

| 19 | Sali Nishanthi | M.Tech | Assistant Professor | Female | 696933111724 | EQIPS3233R | CADCAM | 05.08.2018 | yes | Yes | ||

| 20 | T Anji babu | M.Tech | Assistant Professor | Male | 235668227072 | AZFPT8655E | CADCAM | 20.10.2020 | yes | No | ||

| 21 | V K Satheesh Kumar | M.Tech | Assistant Professor | Male | 871780970376 | EKZPS8108A | CADCAM | 02.10.2017 | No | No | 31.08.2022 | |

| 22 | Smt. P IndraPrasta | M.Tech | Assistant Professor | Female | 536161895093 | CBSPP5125Q | R&AC | 29.06.2019 | yes | No | ||

| 23 | K.Sateesh Kumar | M.Tech | Assistant Professor | Male | 336546991278 | GGTPK3660R | Advanced IC Engines | 25.11.2019 | No | Yes | 31.08.2022 | |

| 24 | B Sreehari | M.Tech | Assistant Professor | Male | 365395493927 | ASEPB7004M | CADCAM | 07.03.2017 | No | Yes | 31.05.2023 | |

| 25 | M Vijaykumar reddy | M.Tech | Assistant Professor | Male | 549863428926 | EEFPS5253L | CADCAM | 05.06.2017 | No | Yes | 26.05.2023 | |

| 26 | ME Annadorai | M.Tech | Assistant Professor | Male | 433647541810 | BQIPA5653E | PEED | 06.01.2020 | No | No | 31.05.2023 | |

| 27 | S Raviteja | M.Tech | Assistant Professor | Male | 485512597847 | EFQPS0614B | Thermal Engineering | 29.07.2019 | No | No | 31.05.2023 | |

| 28 | P Venkatamahesh | M.Tech(Ph.D) | Assistant Professor | Male | 355926107314 | ANNPP8929R | Hydro Electric Engineering | 16.09.2019 | No | Yes | 25.08.2022 | |

| 29 | D Balaji | M.Tech | Assistant Professor | Male | 506813537066 | AQVPD0055F | PEED | 01.10.2020 | No | No | 31.08.2022 | |

| 30 | D Ramakrishna | M.Tech | Assistant Professor | Male | 793275749505 | BEFPD4191H | Machine Design | 05.06.2017 | No | Yes | 31.08.2022 | |

| 31 | K Venkatamuni | M.Tech | Assistant Professor | Male | 914889389183 | AWVPK4007C | PEED | 01.11.2017 | No | No | 27.08.2022 | |

| 32 | K Bharath Kumar | M.Tech | Assistant Professor | Male | 620987881545 | BWFPK1697D | MANUFACTURING | 01.08.2020 | No | No | 30.07.2022 | |

| 33 | S B V J Chandbadshah | M.Tech(Ph.D) | Assistant Professor | Male | 403108474472 | BUNPB8730L | Mechatronics | 20.07.2015 | No | Yes | 31.07.2023 | |

| 34 | T Niranjanbabu | M.Tech | Assistant Professor | Male | 522021077699 | AKDPT7582M | INDUSTRIAL ENGINEERING | 11.03.2017 | No | No | 31.07.2023 | |

| 35 | V Chengal Reddy | M.Tech(Ph.D) | Assistant Professor | Male | 4238 5256 1791 | ANMPV5879K | Machine Design | 29.08.2022 | yes | Yes | ||

| 36 | T Nishkala | M.Tech | Assistant Professor | Female | 735663334066 | AODPN4298L | CADCAM | 29.08.2022 | yes | Yes |

FACULTY MEMBERS IN ACADEMIC YEAR 2021-22

| S. No. | Name | Qualification | Designation | Gender | Aadhar No | PAN No. | Area of Specialization | Date of Joining | Date on which Designated as Professor/ Associate Professor |

Currently Associated (Y/N) |

Ratified (Yes/No) | Date of Leaving (In case Currently Associated is “No”) |

| 1 | Dr. C Nadhamuni Reddy | Ph.D | Principal & Professor | Male | 414306713004 | ABAPC 5515H | Industrial Engineering | 03.08.2015 | 03.08.2015 | Yes | yes | |

| 2 | Dr. S Arul | Ph.D | Professor | Male | 871019584632 | AEXPA9868H | MANUFACTURING | 05.11.2018 | 05.11.2018 | No | yes | 25.05.2022 |

| 3 | Dr. J Venumurali | Ph.D | Professor | Male | 819973470593 | APSPJ6485P | Manufacturing | 10.11.2021 | 10.11.2021 | Yes | yes | |

| 4 | Dr. M Chaitanya Reddy | Ph.D | Associate Professor | Male | 966941696517 | AJCPC4257C | Manufacturing | 24.11.2021 | 24.11.2021 | Yes | yes | |

| 5 | Dr. PC Elumalai | Ph.D | Associate Professor | Male | 374595024048 | AWJPP8360M | Manufacturing | 16.05.2022 | 16.05.2022 | Yes | yes | |

| 6 | K Kumar | M.Tech(Ph.D) | Associate Professor | Male | 308790114558 | BHYPK5057K | Nano Science | 08.08.2011 | 08.08.2011 | Yes | yes | |

| 7 | M Balaji | M.Tech(Ph.D) | Assistant Professor | Male | 754778934056 | CEEPM1233F | Advanced IC Engines | 30.07.2014 | Yes | yes | ||

| 8 | P C Prakash | M.Tech | Assistant Professor | Male | 711696954973 | BPAPP2018B | PEED | 17.12.2015 | Yes | yes | ||

| 9 | S Siva Shankar | M.Tech(Ph.D) | Assistant Professor | Male | 541791092137 | HLZPS2815G | CADCAM | 03.10.2017 | Yes | yes | ||

| 10 | K Rajasekhar | M.Tech | Assistant Professor | Male | 934875350077 | DWZPK0016G | CADCAM | 01.08.2018 | Yes | yes | ||

| 11 | S Praveena | M.Tech | Assistant Professor | Female | 799878705432 | CWCPS4206C | CADCAM | 15.06.2015 | Yes | yes | ||

| 12 | Sali Nishanthi | M.Tech | Assistant Professor | Female | 696933111724 | EQIPS3233R | CADCAM | 05.08.2015 | Yes | yes | ||

| 13 | N V Puneeth Kumar | M.Tech | Assistant Professor | Male | 880261849891 | ARYPN1891P | Mechatronics | 07.06.2017 | Yes | yes | ||

| 14 | D Ramakrishna | M.Tech | Assistant Professor | Male | 793275749505 | BEFPD4191H | Machine Design | 05.06.2017 | No | yes | 31.08.2022 | |

| 15 | K Venkatamuni | M.Tech | Assistant Professor | Male | 914889389183 | AWVPK4007C | PEED | 01.11.2017 | No | No | 27.08.2022 | |

| 16 | S Lakshmi | M.Tech | Assistant Professor | Female | 902690606827 | BCJPA6063R | CADCAM | 08.01.2021 | Yes | yes | ||

| 17 | M Sruthi | M.Tech | Assistant Professor | Female | 548023539960 | CTCPM0520L | Advanced Manufacturing Systems | 01.11.2021 | Yes | yes | ||

| 18 | C.Jay Shyam | M.Tech | Assistant Professor | Male | 495106697257 | AVXPC9841M | PEED | 08.07.2019 | Yes | No | ||

| 19 | T Anji babu | M.Tech | Assistant Professor | Male | 235668227072 | AZFPT8655E | CADCAM | 20.10.2020 | Yes | yes | ||

| 20 | K Gowthami | M.Tech | Assistant Professor | Male | 83066693536 | BZJPK4632F | Machine Design | 01.08.2019 | Yes | yes | ||

| 21 | K.Sateesh Kumar | M.Tech | Assistant Professor | Male | 336546991278 | GGTPK3660R | Advanced IC Engines | 25.11.2019 | No | yes | 31.08.2022 | |

| 22 | P IndraPrasta | M.Tech | Assistant Professor | Female | 536161895093 | CBSPP5125Q | R&AC | 29.06.2019 | Yes | No | ||

| 23 | D Balaji | M.Tech | Assistant Professor | Male | 506813537066 | AQVPD0055F | PEED | 01.10.2020 | No | No | 31.08.2022 | |

| 24 | V K Satheesh Kumar | M.Tech | Assistant Professor | Male | 871780970376 | EKZPS8108A | CADCAM | 02.10.2017 | No | No | 31.08.2022 | |

| 25 | K Bharath Kumar | M.Tech | Assistant Professor | Male | 620987881545 | BWFPK1697D | MANUFACTURING | 01.08.2020 | No | No | 30.07.2022 | |

| 26 | S B V J Chandbadshah | M.Tech(Ph.D) | Assistant Professor | Male | 403108474472 | BUNPB8730L | Mechatronics | 20.07.2015 | No | yes | 31.07.2023 | |

| 27 | B Sreehari | M.Tech | Assistant Professor | Male | 365395493927 | ASEPB7004M | CADCAM | 07.03.2017 | No | yes | 31.05.2023 | |

| 28 | T Niranjanbabu | M.Tech | Assistant Professor | Male | 522021077699 | AKDPT7582M | INDUSTRIAL ENGINEERING | 11.03.2017 | No | No | 31.07.2023 | |

| 29 | M Vijaykumar reddy | M.Tech | Assistant Professor | Male | 549863428926 | EEFPS5253L | CADCAM | 05.06.2017 | No | yes | 26.05.2023 | |

| 30 | ME Annadorai | M.Tech | Assistant Professor | Male | 433647541810 | BQIPA5653E | PEED | 06.01.2020 | No | No | 31.05.2023 | |

| 31 | S Raviteja | M.Tech | Assistant Professor | Male | 485512597847 | EFQPS0614B | Thermal Engineering | 29.07.2019 | No | No | 31.05.2023 | |

| 32 | P Venkatamahesh | M.Tech(Ph.D) | Assistant Professor | Male | 355926107314 | ANNPP8929R | Hydro Electric Engineering | 16.09.2019 | No | yes | 25.08.2022 |

FACULTY MEMBERS IN ACADEMIC YEAR 2020-21

| S. No. | Name | Qualification | Designation | Gender | Aadhar No | PAN No. | Area of Specialization | Date of Joining | Date on which Designated as Professor/ Associate Professor |

Currently Associated (Y/N) |

Ratified (Yes/No) | Date of Leaving (In case Currently Associated is “No”) |

| 1 | Dr. C Nadhamuni Reddy | Ph.D | Principal & Professor | Male | 414306713004 | ABAPC 5515H | Industrial Engineering | 03.08.2015 | 03.08.2015 | Yes | yes | |

| 2 | Dr. S Arul | Ph.D | Professor | Male | 871019584632 | AEXPA9868H | MANUFACTURING | 05.11.2018 | 05.11.2018 | No | yes | 25.05.2022 |

| 3 | K Kumar | M.Tech(Ph.D) | Associate Professor | Male | 308790114558 | BHYPK5057K | Nano Science | 08.08.2011 | 08.08.2011 | Yes | yes | |

| 4 | M Balaji | M.Tech(Ph.D) | Assistant Professor | Male | 754778934056 | CEEPM1233F | Advanced IC Engines | 30.07.2014 | Yes | yes | ||

| 5 | P C Prakash | M.Tech | Assistant Professor | Male | 711696954973 | BPAPP2018B | PEED | 17.12.2015 | Yes | yes | ||

| 6 | S Siva Shankar | M.Tech(Ph.D) | Assistant Professor | Male | 541791092137 | HLZPS2815G | CADCAM | 03.10.2017 | Yes | yes | ||

| 7 | K Rajasekhar | M.Tech | Assistant Professor | Male | 934875350077 | DWZPK0016G | CADCAM | 01.08.2018 | Yes | yes | ||

| 8 | S Praveena | M.Tech | Assistant Professor | Female | 799878705432 | CWCPS4206C | CADCAM | 15.06.2015 | Yes | yes | ||

| 9 | Sali Nishanthi | M.Tech | Assistant Professor | Female | 696933111724 | EQIPS3233R | CADCAM | 05.08.2015 | Yes | yes | ||

| 10 | N V Puneeth Kumar | M.Tech | Assistant Professor | Male | 880261849891 | ARYPN1891P | Mechatronics | 07.06.2017 | Yes | yes | ||

| 11 | D Ramakrishna | M.Tech | Assistant Professor | Male | 793275749505 | BEFPD4191H | Machine Design | 05.06.2017 | No | yes | 31.08.2022 | |

| 12 | K Venkatamuni | M.Tech | Assistant Professor | Male | 914889389183 | AWVPK4007C | PEED | 01.11.2017 | No | No | 27.08.2022 | |

| 13 | S Lakshmi | M.Tech | Assistant Professor | Female | 902690606827 | BCJPA6063R | CADCAM | 08.01.2021 | Yes | yes | ||

| 14 | C.Jay Shyam | M.Tech | Assistant Professor | Male | 495106697257 | AVXPC9841M | PEED | 08.07.2019 | Yes | No | ||

| 15 | T Anji babu | M.Tech | Assistant Professor | Male | 235668227072 | AZFPT8655E | CADCAM | 20.10.2020 | Yes | yes | ||

| 16 | K Gowthami | M.Tech | Assistant Professor | Male | 83066693536 | BZJPK4632F | Machine Design | 01.08.2019 | Yes | yes | ||

| 17 | K.Sateesh Kumar | M.Tech | Assistant Professor | Male | 336546991278 | GGTPK3660R | Advanced IC Engines | 25.11.2019 | No | yes | 31.08.2022 | |

| 18 | P IndraPrasta | M.Tech | Assistant Professor | Female | 536161895093 | CBSPP5125Q | R&AC | 29.06.2019 | Yes | No | ||

| 19 | D Balaji | M.Tech | Assistant Professor | Male | 506813537066 | AQVPD0055F | PEED | 01.10.2020 | No | No | 31.08.2022 | |

| 20 | V K Satheesh Kumar | M.Tech | Assistant Professor | Male | 871780970376 | EKZPS8108A | CADCAM | 02.10.2017 | No | No | 31.08.2022 | |

| 21 | K Bharath Kumar | M.Tech | Assistant Professor | Male | 620987881545 | BWFPK1697D | MANUFACTURING | 01.08.2020 | No | No | 30.07.2022 | |

| 22 | S B V J Chandbadshah | M.Tech(Ph.D) | Assistant Professor | Male | 403108474472 | BUNPB8730L | Mechatronics | 20.07.2015 | No | yes | 31.07.2023 | |

| 23 | B Sreehari | M.Tech | Assistant Professor | Male | 365395493927 | ASEPB7004M | CADCAM | 07.03.2017 | No | yes | 31.05.2023 | |

| 24 | T Niranjanbabu | M.Tech | Assistant Professor | Male | 522021077699 | AKDPT7582M | INDUSTRIAL ENGINEERING | 11.03.2017 | No | No | 31.07.2023 | |

| 25 | M Vijaykumar reddy | M.Tech | Assistant Professor | Male | 549863428926 | EEFPS5253L | CADCAM | 05.06.2017 | No | yes | 26.05.2023 | |

| 26 | ME Annadorai | M.Tech | Assistant Professor | Male | 433647541810 | BQIPA5653E | PEED | 06.01.2020 | No | No | 31.05.2023 | |

| 27 | S Raviteja | M.Tech | Assistant Professor | Male | 485512597847 | EFQPS0614B | Thermal Engineering | 29.07.2019 | No | No | 31.05.2023 | |

| 28 | P Venkatamahesh | M.Tech(Ph.D) | Assistant Professor | Male | 355926107314 | ANNPP8929R | Hydro Electric Engineering | 16.09.2019 | No | yes | 25.08.2022 |

AY: 2023-24

| S.No | Event Organized | Resource Person/Organizer | Date |

| 1. | Webinar on Industrial Revolution | Mr. K. VENKATAKAMESH | 28/11/2023 |

| 2. | Throttles -2K24 | Farewell-Students Event | 4/5/2024 |

| 3 | Hands on Practice on

CATIA |

Mr. Pradeep | 10/01/2024 |

| 4 | Technical Quiz | ME Department | 12/02/2024 |

| 5 | Workshop on Engineering

Graphics |

Dr. K Kumar | 15/11/2023 |

AY: 2022-23

| S.No | Event Organized | Resource Person/Organizer | Date |

| 1 | POWER BI SERVICES | Ms.S.Yashaswini | 24/12/2022 |

| 2. | Routemap for aspirants | Ms.Gayatridevi | 22/12/2022 |

| 3. |

Webinar on SELECTION OF RESEARCH AREA IN MECHANICAL ENGINEERING |

Dr. Jayakrishna Kandaswamy, Professor, SMEC, VIT Vellore,

This webinar is co- ordinated by Dr. B. Sudheer Reddy, Assistant Professor, Dept. of ME |

26/12/2022,

from 2:00 PM to 04:00 PM |

| 4. | One Week Hands-on Training Program on CATIA Software | Mr. A. Rukesh Reddy and Ms. G. Sumohana from ‘Dassault Systemes’. | From Oct. 31st, 2022

to Nov 05th 2022. |

| 5. | MECHXTROM-2K22 | Farewell-Students Event | 02-05-2023 |

AY: 2021-2022

| S.No. | Event Organized | Resource Person/ Organizer | Date |

| 1 | Two-day National workshop on Trouble shooting works on Automobiles (MEEXPLORE -2K21) | Mr. K. VenkataMuni, Manager, Industrial Engineering, from Amararaja Batteries Limited, Tirupati was the Resource person for this workshop. | 1&2 NOVEMBER 2021 |

| 2 | Routemap for aspirants | Mr. Venkatakamesh | 20th Nov 2021 |

| 3 | MECHXTROM-2K21 | Farewell-Students Event | 05-04-2022 |

| 4 | Workshop on Engineering Graphics | Mr. K Kumar | 04-02-2022 |

| 5 | Hands on practice on AutoCAD | CADD Center, Tirupati | 10-03-2022 |

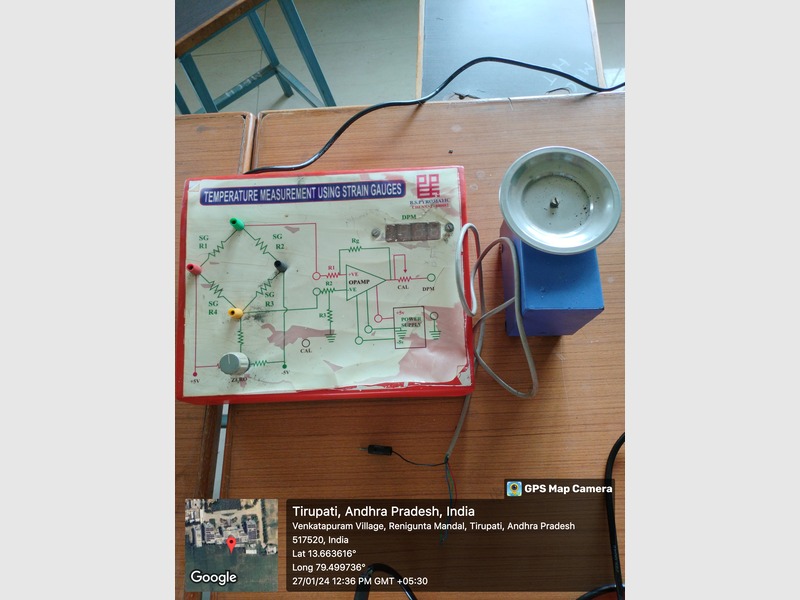

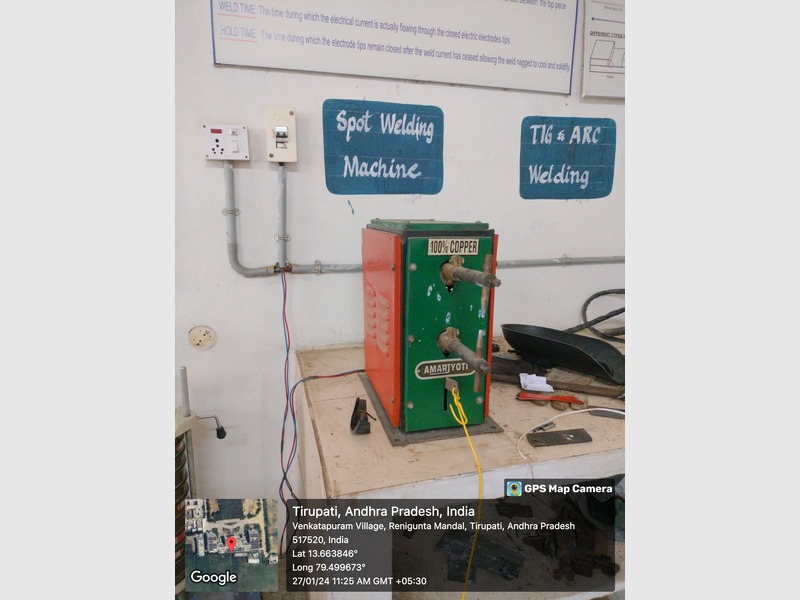

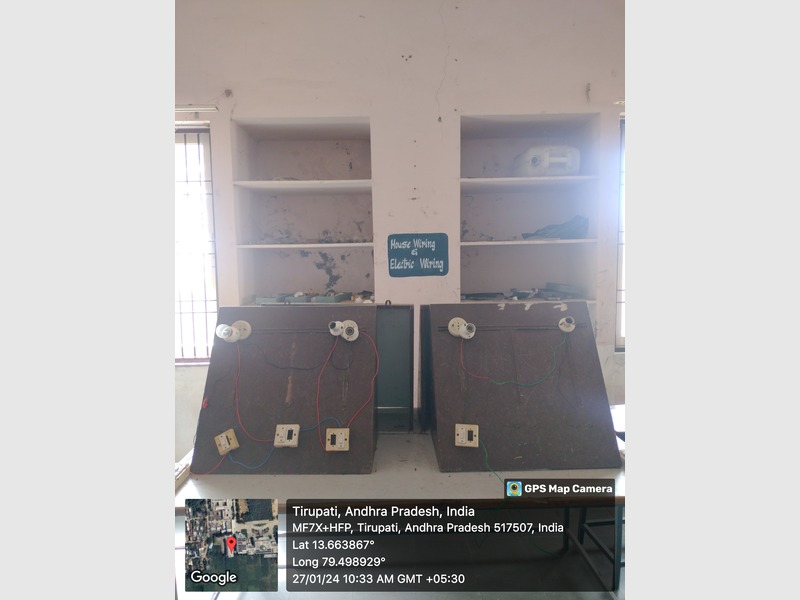

- Engineering Workshop

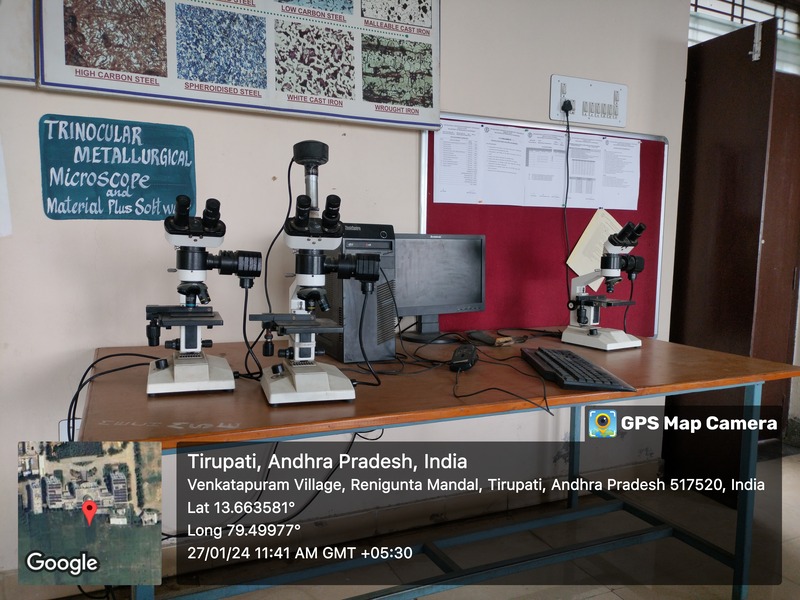

- Material Science Lab & Mechanics of Solids Lab

- Thermal Engineering Lab

- Manufacturing Technology Lab

- Heat Transfer Lab

- Fluid Mechanics & Hydraulic Machinery Lab

- CAD/CAM Lab

- Machine Tools Lab

- Metrology & Measurements Lab

- Computer Aided Engineering Lab

III B.Tech I Semester

| S.no. | Subject Name | File Name |

| 1 | Machine Tools | Machine Tools |

| 2 | Kinematics Of Machines | Kinematics Of Machines |

| 3 | Fluid Mechanics & Hydraulic Machinery | Fluid Mechanics & Hydraulic Machinery |

| 4 | Entrepreneurship Development | Entrepreneurship Development |

| 5 | Introduction To CAD/CAM | Introduction To CAD/CAM |

IV B. Tech I Semester

| S.no. | Subject Name | File Name |

| 1 | Refrigeration & Air Conditioning | Refrigeration & Air Conditioning |

| 2 | English For Research Paper Writing | English For Research Paper Writing |

| 3 | Power Plant Engineering | Power Plant Engineering |

| 4 | Automobile Engineering | Automobile Engineering |

| 5 | Air Pollution and Control | Air Pollution and Control |

PAPERS PUBLISHED 2023-24

| S.NO. | NAME OF THE FACULTY | JOURNAL NAME | YEAR OF PUBLICATION | ISSUE NO | TITLE OF THE PAPER |

| 1 | Dr.C.Nadhamuni Reddy | Journal of Emerging Technologies and innovative research | 2024 | 2349-5162 | A STUDY ON WORKING CAPITAL MANAGEMENT IN APSPDCL, TIRUPATI |

| 2 | Dr.C.Nadhamuni Reddy | International Journal of Advances in Engineering and Management (IJAEM) | 2024 | ISSN (Print): 2395-5252 | A study on performance appraisal system in sri varsha food products india pvt. Ltd. Tirupati |

| 3 | Dr.C.Nadhamuni Reddy | International Journal of Humanities Social Science and Management | 2024 | PP 39-24 | A study on recruitment and selction process at APSPDCL, Tirupati |

| 4 | Dr.C.Nadhamuni Reddy | INTERNATIONAL JOURNAL OF RESEARCH AND ANALYTICAL REVIEWS | 2024 | 2348-1269 | A study on fianacial analysis-ALTMANS’S Z-Score Model in APSPDCL Tirupati |

| 5 | V. Chengal Reddy | Taylor & Francis | 2024 | https://doi.org/10.1080/10426914.2024.2311387 | Comparative analysis and experimental exploration of the milling process in the machining of Inconel 825 material under MQL |

| 6 | V. Chengal Reddy | International Research Journal of Engineering and Technology | 2024 | 2395-0056 | Selection of Optimum Drilling Process Variables Using Grey Relational Analysis Approach |

| 7 | V. Chengal Reddy | Engineering and Technology Journal | 2024 | 2456-3358 | Optimization of Turning Process Performance Characteristics during Machining of AISI 304 Material |

| 8 | T. Nishkala | International Research Journal of Engineering and Technology | 2024 | 2395-0072 | Parametric Optimization of CNC End Milling Process Using Taguchi Method |

| 9 | Dr. M. Maruthi Rao | ECOLOGICAL ENGINEERING & ENVIRONMENTAL TECHNOLOGY | 2023 | 2719-7050 | Wear Analysis of Iron Slag Reinforced Polyester Composites with Taguchi Optimization |

| 10 | Dr. B. Sudheer Reddy | SIRJANA JOURNAL | 2024 | 2455-1058 | Comparative investigations of drive shaft’s design, structure, and modal analysis |

| 11 | Dr. M. Maruthi Rao | Nano world journal | 2023 | 2379-1101 | Experimental Analysis of Closed Loop Pulsating Heat Pipe Working with Water Based Nanofluid at Different Concentrations |

| 12 | Dr. M. Maruthi Rao | Engineering and Technology Journal | 2024 | 2456-3358 | The Effect of Sintering Temperature on Graphene Oxide Reinforced Copper Matrix Composite Fabricated Through Powder Metallurgy Technique |

| 13 | Dr. M. Maruthi Rao | International Research Journal of Engineering and Technology (IRJET) | 2024 | 2395-0056 | DESIGN AND FABRICATION OF PROTOTYPE MODEL MULTI POWER SOURCE VEHICLE |

| 14 | Dr. M. Maruthi Rao | International Journal of Research Publication and Reviews | 2024 | 2582-7421 | Design and Fabrication of Hybrid Power Liner |

| 15 | P. Indraprasta | International Journal of Research Publication and Reviews | 2024 | 2582-7421 | Design and Fabrication of Hybrid Power Liner |

| 16 | S Praveena | International Journal of Research Publication and Reviews | 2024 | 2582-7421 | Design and Fabrication of Hybrid Power Liner |

| 17 | S Praveena | International Research Journal of Engineering and Technology (IRJET) | 2024 | 2395-0056 | Optimization Of Wear Process Parameters On Aluminium Based In-situ Formed TiB2 MMC |

| 18 | Dr. J Venumurali | Surface & Coatings Technology | 2024 | 0257-8972 | Effects of peening duration on surface and wear properties of aircraft graded AA2017 alloy |

| 19 | Dr. J Venumurali | Heliyon | 2024 | 2405-8440 | Impact of infill density on morphology and mechanical properties of 3D printed ABS/CF-ABS composites using design of experiments |

PAPERS PUBLISHED 2022-23

| S.NO. | NAME OF THE FACULTY | JOURNAL NAME | YEAR OF PUBLICATION | ISSUE NO | TITLE OF THE PAPER |

| 1 | Dr. M Chaitanya Reddy | The International Journal of Advanced Manufacturing Technology | 2023 | 0268-3768 | Multi‑response optimization in WEDM process of Al–Si alloy using TLBO‑graph theory algorithm towards sustainability |

| 2 | Dr. M Chaitanya Reddy | Materials Today: Proceedings | 2023 | 2214-7853 | Optimization of process parameters in wire electrical discharge machining using teaching learning based optimization |

| 3 | S. Lakshmi | International Research Journal of Modernization in Engineering Technology and Science | 2023 | 2582-5208 | TESTING MECHANICAL PROPERTIES OF SUGARCANE FIBER & RICE HUSK REINFORCED EPOXY COMPOSITE |

| 4 | S. Praveena | International Journal of Innovative Research in Science, Engineering and Technology | 2023 | 2319-8753 | A Review on IRSM -49/91 Steel on Indian railways |

| 5 | S. Praveena | Journal of Emerging Technologies and innovative research | 2023 | 2341-5162 | Significance of Biot and Grossman Number On Conduction and Convection Heat Transfer for Different Quenching Media |

| 6 | Dr. J Venumurali | Advances in Materials and Processing Technologies | 2022 | 2214-7853 | study on fabrication and mechanical characterization of aluminium hybrid nanocomposites |

| 7 | Dr. M. Maruthi Rao | international journal of scientific research and engineering development(IJSRED) | 2022 | ISSN : 2581-7175 | experimental study of liquid quench media cooling performance by the effect of heat transfer characteristics |

| 8 | Dr. M. Maruthi Rao | International Journal of Scientific Research in Engineering and Management (IJSREM) | 2022 | ISSN: 2582-3930 | TAGUCHI: FACTORS INFLUENCING NOX EMISSIONS FROM A DIESEL ENGINE FUELLED WITH CRUDE RICE BRAN OIL METHYL ESTER BLEND |

PAPERS PUBLISHED 2021-22

| S.NO. | NAME OF THE FACULTY | JOURNAL NAME | YEAR OF PUBLICATION | ISSUE NO | TITLE OF THE PAPER |

| 1 | Dr. J Venumurali | Emerging Trends in Industry 4.0 | 2021 | DOI: 10.1109/ETI4.051663.2021.9619291 | Security vulnerabilities affecting on additive manufacturing systems in the Era of industry 4.0: An extensive review |

| 2 | Dr. M Chaitanya Reddy, | science direct | 2021 | 0925-8388 | An experimental investigation and optimization of energy consumption and surface defects in wire cut electric disacharge machining |

| 3 | Dr.B.Sudheer Reddy | Surface Topography: Metrology and Properties IOP science |

2021 | Online ISSN: 2051-672X | Tribological performance evaluation of h-BN nanoparticle reinforced AA 7075 and as-cast AA7075 using Taguchi and genetic algorithm |

| 4 | S. Siva Sankar | Journal of resource mangement and technology | 2021 | 0745-6999 | Effects of post weld treatment on microstructure and mechanical behavior of friction stir welded thick selection AL-CU Alloy |

PAPERS PUBLISHED 2020-21

| S.NO. | NAME OF THE FACULTY | JOURNAL NAME | YEAR OF PUBLICATION | ISSUE NO | TITLE OF THE PAPER |

| 1 | K. Rajasekhar | International Journal for Modern Trends in Science and Technology | 2021 | 2455-3778 | TRIBOLOGICAL INVESTIGATION OF EPOXY COMPOSITE WITH HARD POWDER |

| 2 | Dr. S. Arul | International Journal of Advanced Research in Science & Technology (IJARST) | 2020 | ISSN (Online) 2581-9429 | Experimental investigation on Cu2O Coated/Non Coated Gear to Compare Enhanced Properties |

| 3 | Dr. J Venumurali | Journal of Minerals and Materials Characterization and Engineering, 2020, | 2020 | ISSN Online: 2327-4085 ISSN Print: 2327-4077 |

Influence of Nanocrystalline Structure on Wear and Corrosion Behavior of Al-SiCp Composite |

| 4 | Dr. J Venumurali | SAE | 2020 | ISSN 0148-7191 | mechanical and microstructures investigation of stir casted aluminuim alloy 8011 -graphene compoistes |

| 5 | Dr. M Chaitanya Reddy | INCAS BULLETIN, Volume 12, Issue 4/ 2020, pp. 33 – 48 | 2020 | ISSN 2066-8201 | An over view of major research areas in wire cut EDM on different materials |

| 6 | K Kumar | International Journal of Advanced Research in Science & Technology (IJARST) | 2020 | ISSN (Online) 2581-9429 | Experimental investigation on Cu2O Coated/Non Coated Gear to Compare Enhanced Properties |

| 7 | K Kumar | International Research journal of Management Science and Technology | 2020 | ISSN:2319-6890)(online),2347-5013 | Experimental Investigation for failure on coated gear by cu2o Nano particles |